AMPTRAN Motor Corporation

Advanced Vehicle Testing Lab

|

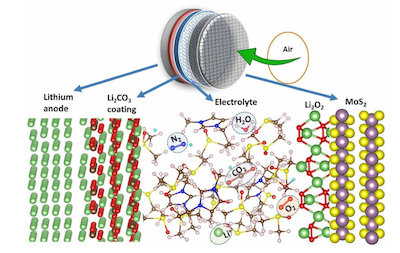

The TECHNOLOGY Rechargeable lithium-air batteries face several challenges. For one, lithium reacts violently with water, so the battery's electrolyte cannot contain any, and water vapor must be separated from incoming air. Lithium in metallic form, which is used in lithium-air batteries, is highly reactive in the presence of even minuscule amounts of water. Turning the lithium oxide—the product of discharging the battery—back to lithium is difficult and only partially possible even when assisted by special catalysts: The oxide builds up and retards the process, limiting the number of charge-discharge cycles to a mere handful. Before lithium-air batteries can find use in hybrid and electric cars, they must be able to handle thousands of such cycles. In addition, the process of charging the Lithium Air battery is a relatively slow process as compared with the Lithium Ion Battery. Most attempts to improve the design of lithium ion batteries have tackled the problem at the macroscopic scale, but work is now focusing on the nanoscale. Nanomaterials were slow to enter the field of energy storage because the effective increase in the electrodes’ surface area raised the risk of secondary reactions involving electrolyte decomposition.

At a nominal electropotential of about 3.27 volts, the theoretical specific energy for a lithium/air rechargeable battery is 5,532 Wh/kg , which is about 10 times that of Li-ion battery chemistry that has a theoretical specific energy of about 400 Wh/kg. The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.

Pairing lithium and ambient oxygen can theoretically lead to electrochemical cells with the highest possible specific energy. Indeed, the theoretical specific energy of a non-aqueous Li–air battery, in the charged state with Li2O2 product and excluding the oxygen mass, is ~40.1 MJ/kg. This is comparable to the theoretical specific energy of gasoline, ~46.8 MJ/kg.

The newly developed Lithium Air Technology will be used to power a typical electric car such as a Chevrolet Bolt to go for 500-600 miles per single charge. Today, the Chevrolet Bolt with lithium ion battery can go only 238 miles per single charge. The Lithium Air Battery technology developed by our team is based on proprietary Nanocomposite Technologies. For more information, please contact us

FOR MORE INFORMATION: please contact: Lithium Air Industries

|

|---|

Copyright © 2011-2021 Lithium Air Industries-. All rights reserved. |