AMPTRAN Motor Corporation

Advanced Vehicle Testing Lab

|

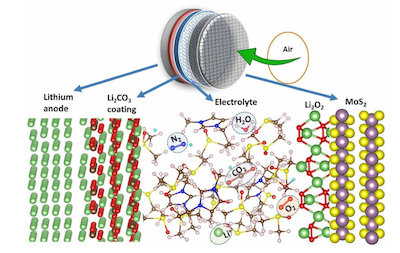

Welcome to Lithium Air Industries, Inc. The mission of the Lithium Air Industries is to develop and produce the state-of-the-art Lithium Air Rechargeable Battery Systems that provide the most high energy density battery products at reasonable costs to meet the needs of the industry. For today's electric vehicles that run on lithium-ion batteries and one of the biggest downsides is the limited range between recharging. Lightweight batteries that can deliver lots of energy are crucial for improving the range of electric cars. For that reason, even modest increases in a battery’s energy-density rating — a measure of the amount of energy that can be delivered for a given weight — are important advances. Over the past 10 years, our team has been working on lithium-air battery, which is estimated could hold 5 to 10 times as much energy as a lithium-ion battery of the same weight and double the amount for the same volume. In theory, the energy density could be comparable to that of gasoline. In a Lithium Air battery, the anode is made of lithium. The cathode is oxygen, drawn from the surrounding air. Instead of carrying Oxygen as a reagent in the battery as in the Lithium Ion battery, the Lithium Air battery use oxygen available abundantly from the environment, thus, we can save weight and volume. As the lithium oxidizes, it releases energy. Pumping electricity into the device reverses the process, expelling the oxygen and leaving pure lithium. While it is currently feasible to have a lithium-air battery for one-time usage, it is a great challenge to make Lithium Air rechargeable. To be able to develop a rechargeable Lithium Air Battery, one need to find the kinds of electrode materials could promote the reversible processes of electrochemical reactions that take place in these batteries. Rechargeable lithium-air batteries face several challenges. For one, lithium reacts violently with water, so the battery's electrolyte cannot contain any, and water vapor must be separated from incoming air. Lithium in metallic form, which is used in lithium-air batteries, is highly reactive in the presence of even minuscule amounts of water. Turning the lithium oxide—the product of discharging the battery—back to lithium is difficult and only partially possible even when assisted by special catalysts: The oxide builds up and retards the process, limiting the number of charge-discharge cycles to a mere handful. Before lithium-air batteries can find use in hybrid and electric cars, they must be able to handle thousands of such cycles. In addition, the process of charging the Lithium Air battery is a relatively slow process as compared with the Lithium Ion Battery. Most attempts to improve the design of lithium ion batteries have tackled the problem at the macroscopic scale, but work is now focusing on the nanoscale. Nanomaterials were slow to enter the field of energy storage because the effective increase in the electrodes’ surface area raised the risk of secondary reactions involving electrolyte decomposition.

The hunt is under way for nanomaterials that can undergo conversion reactions involved multiple electrons at high potential, for use as cathode materials. In collaboration with our partners, NASA Ames Research Center, Lithium Air Industries brings unique expertise in nanotechnology to solve some fundamental problems in the development of Lithium Air battery technologies. Our research team lead by our director Lloyd L. Tran, a nanotechnologist with more than 25 years of experience in technology and business development. The Team focuses on developing Lithium Air Technology that can potentially provide 5-7 times more energy density than the lithium ion battery technologies. The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.

Pairing lithium and ambient oxygen can theoretically lead to electrochemical cells with the highest possible specific energy. Indeed, the theoretical specific energy of a non-aqueous Li–air battery, in the charged state with Li2O2 product and excluding the oxygen mass, is ~40.1 MJ/kg. This is comparable to the theoretical specific energy of gasoline, ~46.8 MJ/kg.

The newly developed Lithium Air technology will be used to power a typical electric car such as a Chevrolet Bolt to go for 500-600 miles per single charge. Today, the Chevrolet Bolt with lithium ion battery can go only 238 miles per single charge. The Lithium Air Battery technology developed by our team is based on proprietary Nanocomposite Technologies. For more information, please contact us FOR MORE INFORMATION: please contact: Lithium Air Industries Email: info@lithiumair.us

|

|---|

Copyright © 2011-2021 Lithium Air Industries-. All rights reserved. |